How to Choose the Right Lightweight Anchoring Systems for Your Project

Wiki Article

How Anchoring Solution Enhance Security and Stability in Various Industries

Securing systems are important for making certain safety and security and security across multiple markets. They supply important support for structures, devices, and employees, mitigating risks connected with side forces and dynamic conditions. From construction websites to maritime environments, these systems offer varied functions. Their performance is frequently considered provided, yet the nuances of their application can substantially influence operational success. Understanding their relevance discloses much deeper insights into market security standards and techniques.The Relevance of Anchoring Equipments in Safety Protocols

Although typically overlooked, anchoring systems play a vital function in guaranteeing safety and security across various sectors. These systems give stability and assistance for structures, devices, and workers, thereby lowering the risk of injuries and mishaps. In settings such as building websites, maritime procedures, and commercial facilities, reliable anchoring assurances that heavy machinery and scaffolding continue to be safe, preventing catastrophic failings. Additionally, proper anchoring systems can boost the efficiency of personal protective equipment, such as harnesses, by anchoring them to secure points, which is essential for workers operating at heights. Using trustworthy securing methods promotes a safety culture, where both monitoring and employees prioritize danger mitigation. Inevitably, the integration of properly designed anchoring systems into safety methods is necessary for keeping operational stability and safeguarding human life, highlighting their importance in daily security procedures across diverse fields.Sorts Of Anchoring Solutions Made Use Of in Building And Construction

In addition, ground supports are important for maintaining structures in challenging terrain, offering resistance against side pressures. Tiebacks and dirt supports are used in excavations and keeping walls to improve stability against soil stress. Each kind of anchoring system is created to satisfy certain load needs and environmental problems, adding to the overall security and longevity of building jobs.Securing Solutions for Maritime Stability

Efficient anchoring solutions are essential for ensuring maritime security, especially in dynamic aquatic atmospheres. These services play an important function in safeguarding vessels, offshore systems, and floating structures versus unpredictable pressures such as waves, currents, and wind. Various types of supports, including conventional stockless supports, drag anchors, and suction supports, are employed based on specific functional needs and seabed conditions.The style and option of anchoring systems are affected by elements such as water deepness, dirt composition, and ecological conditions. Advanced technologies, including vibrant positioning systems and real-time surveillance, additionally boost the effectiveness of securing remedies. By supplying a secure foundation, these systems significantly minimize the threat of capsizing or wandering, thereby guaranteeing the safety of workers and freight. Ultimately, durable anchoring solutions add to the operational performance and durability of maritime properties, highlighting their importance in the maritime market.

Aerospace Applications: Keeping Aircraft Secure

In the aerospace market, ensuring the safety and security of aircraft involves numerous tie-down strategies and freight securing approaches. Compliance with safety and security regulations is vital to preserving security throughout ground procedures and transportation. These methods are necessary for avoiding accidents and guaranteeing the security of both the airplane and its owners.Airplane Tie-Down Techniques

While the safety and security of airplane is paramount, correct tie-down methods serve as a critical component in guaranteeing stability during ground operations. Airplane tie-downs entail protecting the airplane to the ground using ropes, chains, or specialized straps, stopping undesirable activity because of wind or other ecological factors. Effective strategies consist of using appropriate support points and utilizing an adequate number of tie-downs based on the aircraft's size and weight. Regular inspections of tie-down equipment are important to assure integrity and performance. Additionally, understanding neighborhood climate condition can guide the selection of methods and materials utilized for securing airplane. Ultimately, implementing audio tie-down practices boosts operational security and stops damage throughout durations of inactivity.Freight Getting Approaches

Cargo safeguarding techniques play a crucial function in keeping the integrity and security of aircraft throughout transportation. Efficient systems assure that cargo continues to be protected and secure throughout the trip, lessening the threat of movement that could lead to harm or mishaps. Common methods include the usage of freight nets, bands, and specialized securing devices designed to hold up against the pressures experienced during touchdown, takeoff, and flight. The execution of these methods includes cautious preparation and consideration of the cargo's weight circulation and center of mass. Additionally, tools such as tons binders and side protectors improve the general effectiveness of safeguarding methods. By employing these approaches, the aerospace industry considerably decreases prospective dangers connected with carrying products, inevitably securing both the airplane and its freight.Safety And Security Rules Conformity

Guaranteeing compliance with security regulations is vital for keeping the protection of airplane and their freight. In the aerospace sector, rigorous adherence to guidelines set by controling bodies, such as the Federal Aviation Management (FAA) and the International Civil Air Travel Company (ICAO), is vital. These laws mandate using reliable securing systems to secure freight and protect against moving during trip, which can result in mishaps. Proper training for employees in using these systems is also required to verify their performance. Routine examinations and maintenance of securing equipment further boost conformity and security. By adhering to these laws, the aerospace market can significantly reduce threats, safeguard lives, and maintain functional integrity in air traveling.Production Security: Role of Anchoring in Manufacturing

In the domain name of manufacturing, securing systems play a vital role in making sure tools stability and preventing office accidents. By safely fastening equipment, these systems not only boost safety yet also add to operational effectiveness. Reliable securing methods can significantly reduce the danger of incidents, promoting a much safer work environment.Devices Stability Guarantee

The production setting commonly includes hefty machinery and complex equipment, the efficiency of anchoring systems plays a considerable duty in maintaining equipment stability. Correctly set up supports reduce resonances and avoid devices from changing throughout procedures. This security is important for both the performance of equipment and the general efficiency of production procedures. Additionally, well-anchored equipment minimizes wear and tear, extending the life expectancy of expensive properties. In settings where accuracy is vital, such as assembly lines, the guarantee of security given by securing systems improves operational accuracy. Incorporating robust anchoring services into manufacturing arrangements not just safeguards equipment yet additionally cultivates a dependable production landscape, ultimately contributing to enhanced outcome and performance.Stopping Office Accidents

Anchoring systems greatly add to avoiding workplace crashes in producing environments. By safeguarding machinery and tools, these systems decrease the danger of tipping, falling, or changing during procedure. This stability is essential, as unanchored devices can lead to significant injuries among employees and damage to home. On top of that, anchoring systems improve the effectiveness of safety methods, as they offer a reputable structure for precaution such as guardrails and safety and security internet. Regular assessments and upkeep of securing systems are vital to guarantee their integrity, consequently cultivating a society of security within the work environment. Ultimately, a durable anchoring system is a fundamental element in developing a safer production atmosphere, lowering the possibility of crashes and promoting overall office security.Boosted Functional Effectiveness

Enhancing functional performance in making relies considerably on efficient securing systems. These systems provide security to machinery and tools, reducing resonances and movement throughout manufacturing processes. By making sure that tools and elements continue to be firmly in position, securing systems reduce the danger of functional delays created by tools imbalance or failing. This dependability permits smoother process and boosted efficiency, as workers can focus on their tasks without continuous adjustments or disruptions. Additionally, effective anchoring contributes to the durability of machinery, minimizing upkeep prices and downtime. Because of this, producers can accomplish higher output rates and enhanced source application, inevitably bring about higher earnings and an one-upmanship out there.

Developments in Anchoring Innovation

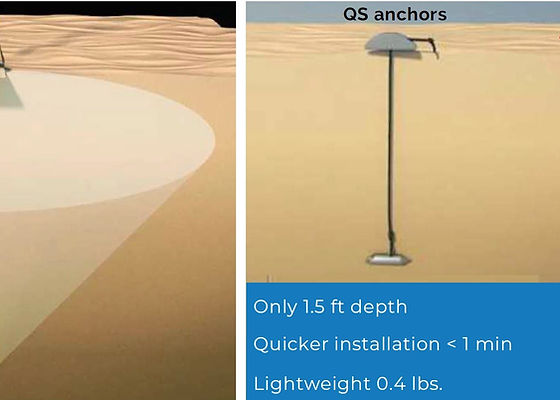

As the demands for safety and stability in various markets boost, technologies in view publisher site anchoring innovation have actually arised to attend to these challenges. Modern anchoring systems are currently created with sophisticated products and design techniques, enhancing their longevity and effectiveness. Innovations such as clever sensors and automated monitoring systems allow for real-time assessment of securing efficiency, making certain ideal precaution are preserved.Additionally, lightweight composite products have actually changed conventional steels, decreasing the overall weight of securing systems while improving strength. Modular styles offer flexibility, permitting easy adjustments and personalizations to meet certain functional requirements. Furthermore, green anchoring remedies are acquiring traction, lessening environmental influence while making certain robust performance.

These improvements not only boost the reliability of anchoring systems but also resolve the evolving needs of varied industries, consisting of building, marine, and eco-friendly power industries. Such developments lead the way for more secure and a lot more efficient procedures across numerous applications.

Case Researches: Successful Application of Anchoring Systems

The improvements in securing innovation have resulted in notable case studies showcasing successful applications throughout different sectors. In the construction market, a major job utilized a brand-new kind of deep structure anchoring system, which boosted stability in difficult soil conditions. This technology considerably decreased negotiation issues and ensured safety and security throughout construction, ultimately causing prompt project completion.In the maritime field, a shipping business embraced sophisticated mooring systems that improved vessel stability during site link negative climate conditions. This application led to a marked reduction in mishaps and freight losses, underscoring the significance of reliable anchoring in unpredictable settings.

Additionally, in the wind energy sector, anchoring systems have actually been essential in safeguarding overseas wind turbines against strong currents, showing their function in sustainable energy production (Lightweight Anchoring Systems). These case research studies collectively show exactly how efficient anchoring services add to security, performance, and lasting viability throughout varied markets

Regularly Asked Concerns

How Do Anchoring Equipment Affect Overall Job Timelines?

The efficiency of job timelines can be substantially affected by securing systems. Correct anchoring minimizes hold-ups by guaranteeing stability, reducing dangers, and facilitating smoother procedures, inevitably adding to prompt job conclusion and boosted productivity.Are There Particular Laws Governing Anchoring Solutions?

Certain laws governing securing systems exist across different industries, ensuring conformity with safety requirements. Site Security Anchors. These regulations usually concentrate on setup, layout, and maintenance, targeted at decreasing risks and improving total operational stability and security

What Products Are Generally Used in Anchoring Systems?

Typical products utilized in anchoring systems consist of high-strength steel, galvanized iron, synthetic ropes, and composite products. These elements are chosen for their sturdiness, resistance to environmental factors, and capacity to offer dependable support in various applications.

Just How Typically Should Anchoring Systems Be Checked?

Evaluation frequency for securing systems typically depends on use and ecological conditions. Typically, it is recommended to perform evaluations every six months, with even more frequent checks in rough settings or adhering to substantial occasions impacting security.What Are the Prices Related To Setting Up Anchoring Solutions?

The prices related to mounting anchoring systems differ considerably based upon variables such as products, design complexity, and labor needs. Proper budgeting is crucial to assure effective application and compliance with security policies in appropriate industries.Anchoring systems are vital for making certain safety and security and stability throughout multiple markets. Usually ignored, securing systems play a necessary role in ensuring safety throughout numerous sectors. look at here now In enhancement, securing systems improve the efficiency of security procedures, as they supply a dependable foundation for safety and security actions such as guardrails and safety nets. Normal inspections and maintenance of anchoring systems are important to ensure their integrity, thus fostering a culture of security within the office. Particular laws controling securing systems exist throughout numerous sectors, making certain conformity with security standards.

Report this wiki page